Before you go...

Are you sure you want to leave this page?

The quote progress wil be saved.

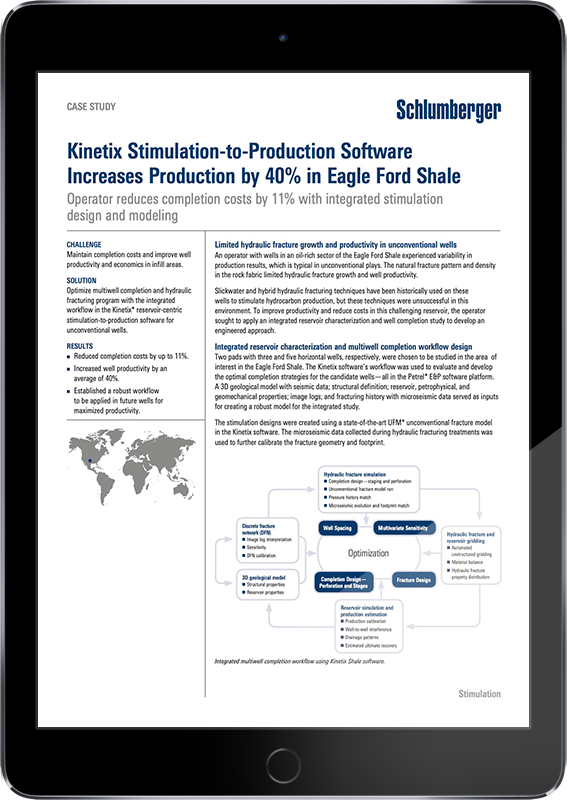

An operator with wells in an oil-rich sector of the Eagle Ford Shale experienced variability in production results, which is typical in unconventional plays. The natural fracture pattern and density in the rock fabric limited hydraulic fracture growth and well productivity.

Slickwater and hybrid hydraulic fracturing techniques have been historically used on these wells to stimulate hydrocarbon production, but these techniques were unsuccessful in this environment. To improve productivity and reduce costs in this challenging reservoir, the operator sought to apply an integrated reservoir characterization and well completion study to develop an engineered approach.